Chair caning right at your doorstep in the Boston, Massachusetts area. Our 10-person woodworking staff re-canes chairs and other furniture pieces on a regular basis, and we want to help with yours!

Have a damaged chair you need re-caned?

Send us a photo here!

Want to know what type of cane you have? Read on…

Chair caning is a method of weaving or affixing rattan peel to a piece of furniture. There are two basic types of caning — ‘pressed cane’ and ‘hand cane,’ along with a subtype of hand cane called ‘blind cane’ or ‘French cane.’ Pricing is dependent on the caning type and the size of the panels.

Pressed cane involves precisely measuring and cutting pre-caned rolls to match the dimensions of the original panel, and then using a special hand tool to insert the edges into a groove or channel in the wood. Once affixed, a spline is attached around the edge for protection and cosmetic appearance.

The top of a pressed cane seat panel at our workshop. You can see that the cane is pressed into a groove. If you were to look underneath, you would not see any holes in the wood with cane threaded through them.

Hand cane involves using individual strands of cane that are measured and cut, soaked for flexibility, and then interwoven to create a panel from scratch. The strands are threaded through pre-drilled holes in a chair’s framework and tied by hand underneath or behind the seat or back.

The top and bottom of a hand caned seat panel at our workshop. Looking at the top only, you can see where the cane wraps around the spline to enter each drilled hole in the wood. If you look under the seat of this chair, you can see the cane threaded through the holes.

‘French cane’ or ‘blind cane,’ a subset of hand cane, was occasionally used on antique furniture pieces. This is an advanced technique where strands of cane are threaded into partially drilled holes that do not come out on the other side. Each strand is individually cut, woven, and secured with glue and pegs. It is very labor intensive both to remove and reproduce.

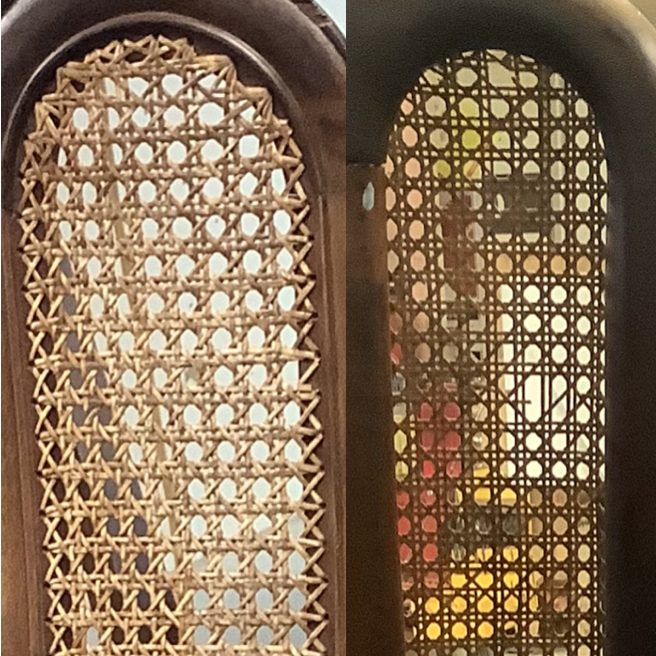

The front and back of a blind cane (or French cane) back panel at our workshop. Blind cane is almost never used on seats. The cane is threaded into partially drilled holes that do not come out the other side, and it is held in with glue. Blind cane can sometimes look like regular hand cane from the front!

People commonly confuse other types of woven seats and backs with cane. Here are some that we replace!

This is a rush stool at our workshop. Rush is a hand-woven seat replacement process using individually harvested cattails that are spun into a thick ‘yarn’ and interwoven onto and throughout a chair seat. It is labor and time-intensive and is one of the more costly of chair seat replacements.

This is a Danish cord chair at our workshop. Danish cord is a hand-woven process that uses strong, 3-ply paper cords interwoven over and throughout the seat. It is labor and time-intensive and is one of the more costly of seat replacements. Danish cord is occasionally woven in a rush pattern.

This is a shaker tape chair that came to our workshop. Shaker tape is a strong, heavy-duty cotton canvas webbing, historically used by the Shaker community to weave durable, comfortable, and sometimes colorful seats, often in classic checkerboard patterns or alternative designs like herringbone.

Have a chair you need re-caned, re-rushed, re-corded, or re-woven with shaker tape?

Follow the instructions on our contact page to send us a photo!